what is compression moulds?

Compression mould usually use hydraulic press machine and the cavity and core is fixed to top and bottom platens of machine. Once the material is placed into the open mould, the machine closes, mould get heated, then the press pressure force material to flow all over the mould.

In above process, the material which placed into open mould are normally SMC, BMC,GMT etc compound material. So we always refer this type of comperssion mould to SMC mould, BMC mould, GMT mould.

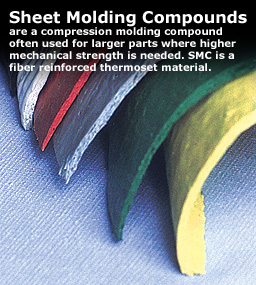

There are certian difference between SMC, BMC and GMT material. SMC(sheet molding compounds) is a fiber reinforced thermoset material often used for large parts where highr strength is needed

Click for details

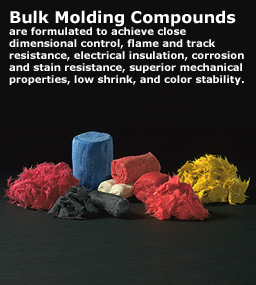

BMC (Bulk molding compounds) are characterised by its doughy texture and short fiber.

GMT (Glass Fiber Mat Reinforced Thermoplastics)can also be recycled.

Only GMT material need to be preheated.

Instead of cooling channel in injection mould, SMC mould require a heating channel. Normal heating systems are steam, oil, electricity or high perssure water.

The working temperature of the SMC mould is usually 140 degree to 160 degree. When designing the termprature system it is essential to be abe to keep the surface of the mould within close temprature. A mould with uniform temperature will fill easier and produce parts with less warpage, imprived dimensional stability and a uniform surface appearance.

Instead of cooling channel in injection mould, SMC mould require a heating channel. Normal heating systems are steam, oil, electricity or high perssure water.

The working temperature of the SMC mould is usually 140 degree to 160 degree. When designing the termprature system it is essential to be abe to keep the surface of the mould within close temprature. A mould with uniform temperature will fill easier and produce parts with less warpage, imprived dimensional stability and a uniform surface appearance.

Compression Mould Design Points

SMC mould design follows similar rules as for any other production process with the plastic industry. But before you build a SMC mould, there are certain things need to be considered.The first and most important is shear edge. Mould shrinkag

There are two shrinkage for SMC mould. Low profile class A part have a shrinkage of -0.05% to 0%.

Heating System:

SMC and BMC need heating channel instead of cooling. The working temperature of the mould is usually at 140 degree to 160 degree. When designing the temperature system it is important to keep surface temperature within very close parameters. Mould will fill easier and produce parts with less warpage, and uniform surface appearance. The mould can be heated by steam, or oil, or electricity or even high pressure water.

Vacuum System:

To achieve a better appearance of part will require vacuum assistance. For more information please contact our technician.

Production SMC Mould:

Production mould must be of highest quality and capable of making parts consistently and economically. Ningguang Mould will help you to achieve that.

There are two shrinkage for SMC mould. Low profile class A part have a shrinkage of -0.05% to 0%.

Heating System:

SMC and BMC need heating channel instead of cooling. The working temperature of the mould is usually at 140 degree to 160 degree. When designing the temperature system it is important to keep surface temperature within very close parameters. Mould will fill easier and produce parts with less warpage, and uniform surface appearance. The mould can be heated by steam, or oil, or electricity or even high pressure water.

Vacuum System:

To achieve a better appearance of part will require vacuum assistance. For more information please contact our technician.

Production SMC Mould:

Production mould must be of highest quality and capable of making parts consistently and economically. Ningguang Mould will help you to achieve that.

Click for details

SMC Mould Applications

SMC and BMC in the automotive industry

Composites are used in automotive and truck industry for over 50 years now. Major reasons for automotive are weight reduction and design freedom as also cost competitiveness. SMC and BMC are widely used for exterior body panels. SMC and BMC are the best solution for weight reduction on a vehicle while stiffness or temperature performance or on-line paintability are basic demands and are also provided.

Since car bodies made of SMC / BMC have been realised (examples Chevrolet Corvette & Camaro, Renault Espace, Pontiac Fiero, GM Lumina APV and DC Viper, Renault Avantime, VOLVO ES 480) ,we can see structural components made of SMC coming up soon using the potential for more weight reduction.

Since car bodies made of SMC / BMC have been realised (examples Chevrolet Corvette & Camaro, Renault Espace, Pontiac Fiero, GM Lumina APV and DC Viper, Renault Avantime, VOLVO ES 480) ,we can see structural components made of SMC coming up soon using the potential for more weight reduction.

Click for details

Features, Advantages and Benefits of SMC / BMC parts:

Perfect surface

On-line, in-line and off-line paintable

Parts integration

Light weight

Low system cost

Integration of functions

Easy to bond

Stiff

Good mouldability

Complex shape

Weathering resistance

Low moulding pressure

Low tooling cost

No corrosion

High stiffness & strength

On-line, in-line and off-line paintable

Parts integration

Light weight

Low system cost

Integration of functions

Easy to bond

Stiff

Good mouldability

Complex shape

Weathering resistance

Low moulding pressure

Low tooling cost

No corrosion

High stiffness & strength

Cost comparison of SMC versus sheet metal:

Nowadays, car manufactures diversify their product portfolio significantly. Using the same platform with different body work leads often to annual number of vehicles between 30.000 and 100.000. Here MenzolitSMC offers not only weight savings but also – and that is even more important – a cost advantage.

Following we are showing a cost comparison of a tailgate made of Steel vs. SMC.

The tailgate is made from an inner support and an outer skin which are bond together and then painted. If the tailgate is made from sheet metal the aprts are welded sealed and corrosion protected before painting. To form these parts from metal 5 to 6 tools for the outer skin and further five for the inner shell are necessary. For SMC only one tool needed for inner and outer part for volumes up to 60.000 and 2 of each for twice the volume. Exceeding these numbers up to 80/160.000 an additional tool per shell is advised to have delivery security. With high volumes sheet metal is definite the more inexpensive alternative.

Following we are showing a cost comparison of a tailgate made of Steel vs. SMC.

The tailgate is made from an inner support and an outer skin which are bond together and then painted. If the tailgate is made from sheet metal the aprts are welded sealed and corrosion protected before painting. To form these parts from metal 5 to 6 tools for the outer skin and further five for the inner shell are necessary. For SMC only one tool needed for inner and outer part for volumes up to 60.000 and 2 of each for twice the volume. Exceeding these numbers up to 80/160.000 an additional tool per shell is advised to have delivery security. With high volumes sheet metal is definite the more inexpensive alternative.

Cost comparison of tailgates made from sheet metal versus SMC:

End of life of vehicle:

The ELV regulation of the EU requires a detailed evaluation of parts used on the vehicle regarding ecological behaviour and recyclability.

Therefore a decklid concept was evaluated under the parameters of an eco balance and three models were compared to each other: aluminium, sheet metal and SMC.

SMC shows the best eco-efficiency.

Therefore a decklid concept was evaluated under the parameters of an eco balance and three models were compared to each other: aluminium, sheet metal and SMC.

SMC shows the best eco-efficiency.